Regeneration and Preparation of Waste PET Films: Current Status, Technologies and Prospects(1)

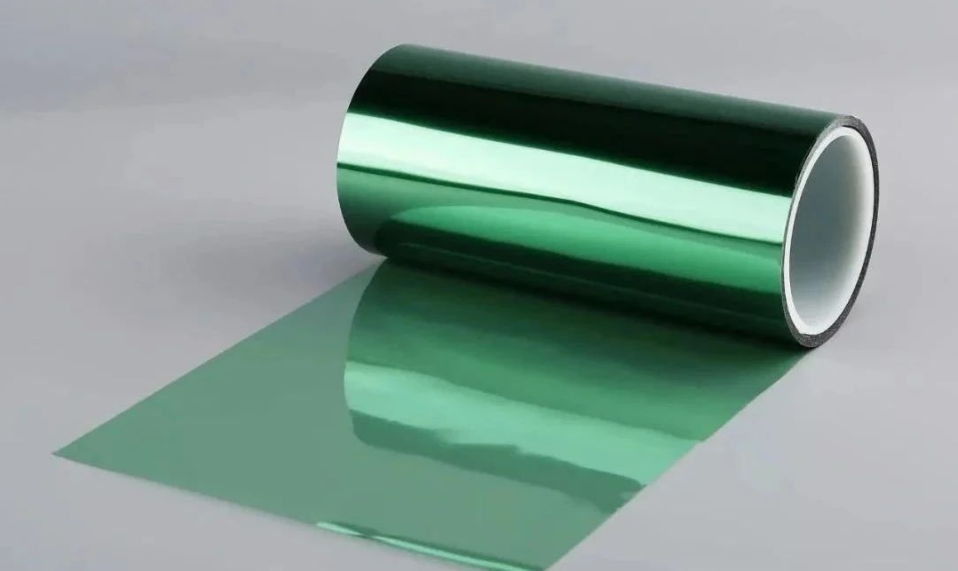

With the vigorous development of the electronics industry, polyethylene terephthalate (PET) films play an indispensable role in the manufacturing of numerous electronic products due to their excellent insulation, high transparency, good mechanical properties, and chemical stability. These applications include multi-layer ceramic capacitors (MLCC), flexible circuit boards, liquid crystal displays, and more. However, with the rapid expansion of the electronics industry, the generation of waste PET films has been increasing day by day. If these waste films are not properly disposed of, they will not only cause enormous waste of resources but also impose a heavy burden on the environment. Therefore, achieving efficient regeneration and preparation of waste PET films in the electronics industry is of far-reaching and significant importance for promoting the sustainable development of the electronics industry, alleviating resource pressure, and reducing environmental pollution.

Sources and Characteristics of Waste PET Films in the Electronics Industry

Diverse Sources

In the electronics industry, waste PET films originate from a wide range of sources:

MLCC production: PET films are used to form dielectric sheets, generating substantial edge trimmings and discarded materials after manufacturing.

Flexible circuit board manufacturing: As a substrate material, PET films produce waste due to cutting processes, process defects, or other imperfections.

Liquid crystal display (LCD) fabrication: PET films are applied in components like polarizers and diffuser films, with defective products and cuttings during production contributing to waste accumulation.

Complex and Unique Characteristics

Compared to ordinary PET films, waste PET films in the electronics industry exhibit distinct properties:

Exposure to various chemicals and special processing techniques in electronic manufacturing may lead to contamination by metal impurities, organic pollutants, and cross-linked structures of varying degrees.

For example, PET waste from MLCC production may adhere to metal oxide particles due to contact with ceramic slurries.

PET waste from flexible circuit boards may retain organic substances like photoresist residues from lithography and etching processes.

These complex characteristics pose significant challenges to the regeneration and preparation of waste PET films.

Regeneration and Preparation Technologies for Waste PET Films

Physical Recycling Technologies

Cleaning and Crushing

The cleaning process aims to remove surface dust, oil stains, and other soluble impurities from waste PET films. Common methods include alkali washing, acid washing, and organic solvent cleaning:

Alkali washing effectively removes oil stains.

Acid washing dissolves partial metal impurities.

Organic solvent cleaning is significant for removing organic pollutants.

Crushing involves breaking the cleaned PET films into fragments of specific sizes using crushers, facilitating subsequent processing. In practice, the selection of cleaning reagents and crushing equipment must be tailored to the contamination degree and characteristics of the waste films to ensure thorough cleaning and uniform particle size.

Melt Extrusion

The crushed PET fragments are heated above their melting point (typically 250–260°C) to form a melt, which is then extruded through an extruder, followed by cooling and pelletizing to produce regenerated PET pellets.

Additives like plasticizers and antioxidants are often incorporated to improve the properties of regenerated PET. For example, plasticizers enhance flexibility, while antioxidants boost thermal stability.

However, molecular chain degradation of PET may occur during this process, reducing product performance. Strict control of processing temperature, time, and screw rotation speed is essential to minimize degradation.

Solid-State Polycondensation (SSP)

SSP is a key method to increase the molecular weight and performance of regenerated PET. Regenerated PET pellets are heat-treated at temperatures below the melting point (typically 200–220°C) under an inert gas atmosphere.

Through SSP, polycondensation reactions between PET molecular chains increase the molecular weight, thereby improving the strength and heat resistance of regenerated PET.

Challenges include long processing times and strict requirements for equipment airtightness and temperature control precision.

Chemical Recycling Technologies

Alcoholysis

Alcoholysis involves reacting waste PET films with alcohols (e.g., ethylene glycol, propylene glycol) under a catalyst to decompose PET into monomers or oligomers like bis(2-hydroxyethyl) terephthalate (BHET).

Take ethylene glycol alcoholysis as an example: the reaction temperature is controlled at 180–220°C, with catalysts such as zinc acetate or tetrabutyl titanate. After reaction, BHET is separated via filtration and distillation, then refined for PET resynthesis.

This method effectively removes impurities to obtain high-purity regenerated materials but requires harsh reaction conditions and corrosion-resistant equipment.

Hydrolysis

Hydrolysis decomposes waste PET films into terephthalic acid (PTA) and ethylene glycol using water under high temperature and pressure, categorized into acidic, alkaline, and neutral hydrolysis:

Acidic hydrolysis: Uses strong acids (e.g., sulfuric acid, hydrochloric acid) as catalysts, featuring fast reaction rates but severe equipment corrosion.

Alkaline hydrolysis: Employs strong bases (e.g., sodium hydroxide, potassium hydroxide), with easy product separation but requiring subsequent neutralization.

Neutral hydrolysis: Operates under high temperature/pressure without acid/base catalysts, environmentally friendly but demanding stricter conditions and higher equipment investment.

Hydrolysis completely decomposes PET, with products directly usable for PET synthesis, but suffers from high energy consumption and complex separation/purification processes.

Pyrolysis

Pyrolysis heats waste PET films at high temperatures (400–600°C) in an oxygen-free or oxygen-deficient environment, causing thermal decomposition into small molecules like aromatic compounds (benzene, toluene, xylene) and olefins/alkanes.

Pyrolysis products can be utilized as chemical raw materials, enabling energy-oriented recycling of waste PET films. However, the complex product mixture poses challenges for separation/purification, and harmful gases may require a complete tail gas treatment system.

Exploration of Novel Recycling Technologies

Electrocatalytic Recycling

In recent years, electrocatalytic recycling has emerged. For example, a research team led by Professor Zhao Yixin from Shanghai Jiao Tong University used electrocatalytic technology to selectively convert ethylene glycol in PET hydrolysate into formic acid at room temperature and pressure, while co-producing hydrogen at the cathode.

This technology uses renewable electricity as an energy input, providing a new pathway for resource conversion of waste PET films. Efficiency and selectivity can be improved by optimizing electrode materials and reaction conditions.

Currently, electrocatalytic recycling remains in the laboratory research stage, with technical challenges for industrialization, such as electrode stability and large-scale system design.

Combination of Biodegradation and Synthesis

Some microorganisms secrete enzymes that degrade PET. Using these microorganisms or their enzymes, waste PET films are broken down into small molecules, which are then biosynthesized into PET or other biobased materials.

This approach offers advantages like environmental friendliness and mild reaction conditions, but suffers from slow biodegradation rates and complex biosynthesis regulation. It is still in the exploratory stage, requiring in-depth studies on microbial metabolic mechanisms and biosynthesis process optimization.

Applications of Regenerated PET in the Electronics Industry

Substitution of Partial Virgin Materials

After a series of processing, the properties of regenerated PET are significantly improved, enabling it to substitute virgin PET materials in the electronics industry to a certain extent. Regenerated PET has been widely used in electronic product components with relatively low performance requirements, such as ordinary electronic packaging materials and casings of some electronic devices.

For example, packaging boxes of certain electronic products made from regenerated PET not only reduce costs but also decrease dependence on virgin resources.

In the manufacturing of electronic device casings, adding appropriate reinforcing materials and additives allows regenerated PET to meet requirements for strength and heat resistance, achieving green manufacturing of casings.

Expansion to New Application Fields

With continuous improvements and innovations in the properties of regenerated PET, its application scope in the electronics industry is gradually expanding. In emerging electronic fields such as wearable devices and flexible electronic devices, regenerated PET is expected to become an important basic material due to its excellent flexibility and processability.

For instance, in components of wearable devices like flexible circuit board substrates and display protective films, regenerated PET materials can leverage their advantages to achieve lightweight and sustainable product development.

Meanwhile, in electronic devices requiring electromagnetic shielding performance, modifying regenerated PET through special treatments (e.g., adding conductive fillers) can produce materials with electromagnetic shielding functions, expanding the application range of regenerated PET.